My Bebarfald Bluebird is an early twentieth century vibrating shuttle (VS) treadle sewing machine. It’s also Australian. Well, at least partly …

I’ve had a lot of fun servicing my Bluebird and discovering its history.While the cabinet and the treadle were definitely made in Australia by furniture manufacturer Bebarfalds Ltd, the actual sewing machine is another matter. It may have been made in a specialty Bebarfald factory in in the 1920s, or it could be an import rebadged with the Bebarfald Blue-Bird logo.The serial number under the base is 44249 and the bobbin winder has 1891 stamped on it. But that, so far, has not helped me identify the manufacturer or original date of manufacture.

I would have been quite lost if it wasn’t for Cyndy’s shop, Cyndy Kitt Productions, where she supplies a lot of useful stuff for vintage treadle machines plus some very useful expertise on Bebarfald Bluebirds. Also check out her offerings on ebay and etsy.

I replaced the bobbin winder tire and got some Singer-style long bobbins that, while not identical to the one that came with my machine, can be wound with the aid of blue-tack. Unlike the Singer bobbins, my Bluebird bobbin has five holes in the end plate so that one hole will lock onto a little spike inside the bobbin winder.

I now have a copy of a manual originally printed in the late twenties or early thirties. And Illustration 3 looks exactly like my machine. So that’s a good start. But subsequent illustrations show a different arrangement for threading the machine to wind the bobbin – so I had to guess. The bobbin wound beautifully the first time. I have yet to duplicate this initial burst of beginner’s luck as you can see in the photo below a very unevenly wound bobbin. The bobbin with the thread on came with the machine. The other is the Singer-style substitute:

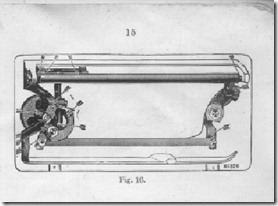

Servicing a machine like this is generally quite easy. Below is a diagram of the mechanics of a Singer 99 from the side and from underneath. The basic mechanics of early twentieth century machines seem to be much the same: beautiful in their simplicity.

All I had to do was get in from the sides and underneath, clean those moving metal bits and pieces with WD40 and then oil them with sewing machine oil. Same thing with the treadle mechanism.

I haven’t yet taken apart the wheel brake disconnector to clean and oil it. There are signs that this may be necessary because the needle bar occasionally moves when I am winding the bobbin. I’m a bit nervous about this because the only information I have is for a Singer.So I think I’ll try this first on my Singer 99K first. My 99K wheel brake disconnector doesn’t work at all and definitely needs looking at. There’s a great tutorial here on the Vintage Singer Sewing Machine Blog.

Right now I’m adjusting the thread tension on the Bebarfald. More about this later. With luck I will return to report a perfectly balanced lockstitch.

I also have a Bebarfald in a beautiful lead light cabinet. I love the history behind these machines. I was under the understanding that the machine itself could be a rebadged Pfaff. Not sure how accurate that is as I haven't investigated further yet. Thanks for sharing some information about your machine. I have bought from Cyndy Kitt for my Singers and agree that she is great

ReplyDelete